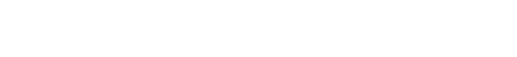

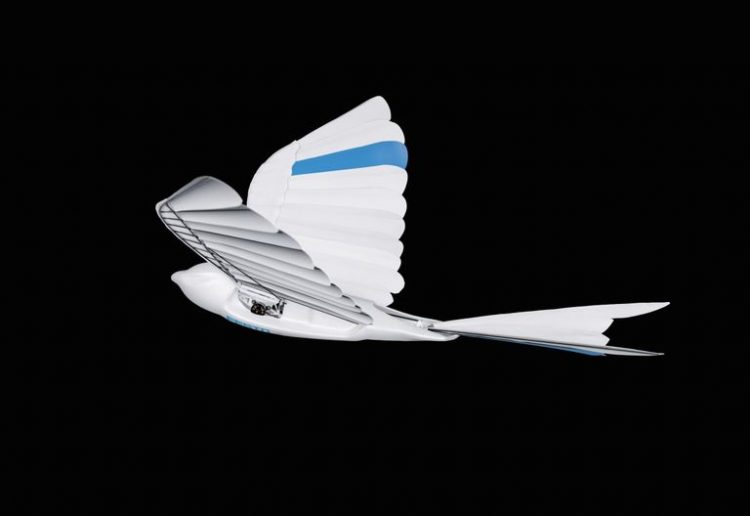

German automation company Festo recently unveiled its latest bio-inspired creation, the Bionic Swift, a lightweight robot capable of mimicking the flight of an actual swift.

Over the last decade Festo has unveiled an impressive number of robots inspired by the Earth’s fauna, from bionic ants and butterflies, to penguins, jellyfish and even kangaroos. Earlier this month, the robotics studio showcased their newest invention, a lightweight flying robot inspired by the swift and capable of mimicking its flight maneuvers with impressive accuracy. From steep turns and drops to nausea-inducing loops, the new Bionic Swift can pull of most, if not all, of a real swift’s movements.

Photo: Festo

In order to imitate real swifts, Festo’s robotic versions had to be ultra-light, weighing in at a meager 42 grams each, or about as heavy as a golf ball. The birds are about 17.5 inches long, with a 27-inch wingspan, but don’t look much like birds from up-close, as the company’s designers focused more on bio-mimicry than exterior design.

Although the Bio Swift’s feathers are not real – they are made of light foam – they do look and behave like the ones of a real swift in flight. They are connected to a carbon quill and can seamlessly slide apart just like real feathers, thanks to the ingenious design of the robot’s wings. The feathers also overlap, as shingles on a roof, and can move to let air through or close completely, allowing the Bio Swift to execute impressing flight maneuvers.

Photo: Festo

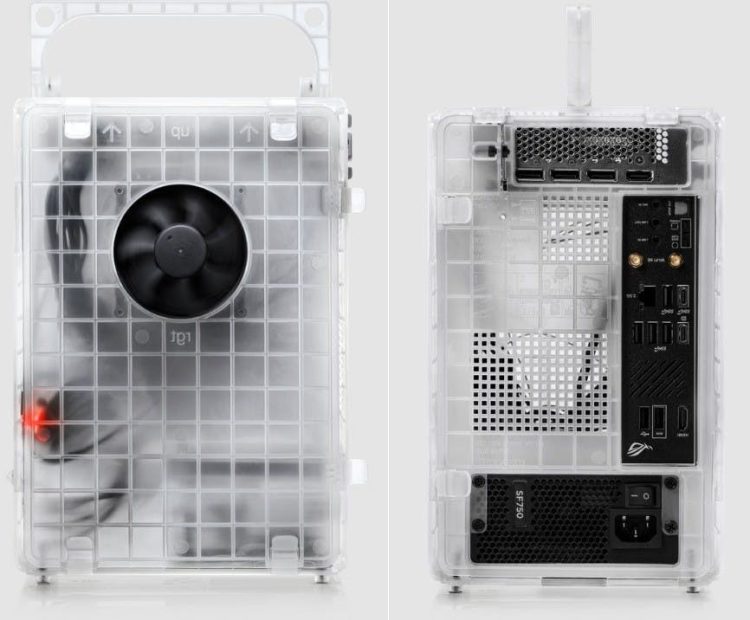

Despite its small weight, each Bio Swift houses a brushless motor, two servo motors, a battery, a gear unit, and various circuit boards for radio, control, and localization. Thanks to a radio-based indoor GPS, each robot has spatial awareness and can fly in a coordinated pattern. Each one has a radio marker that sends signals to the base, thus allowing the system to locate each bird’s exact location and tell them to fly on a pre-programmed path.

Apart from being visually impressive, the new Bio Swifts may soon start helping companies precisely monitor where goods are moving throughout a smart factory, thus avoiding bottlenecks.