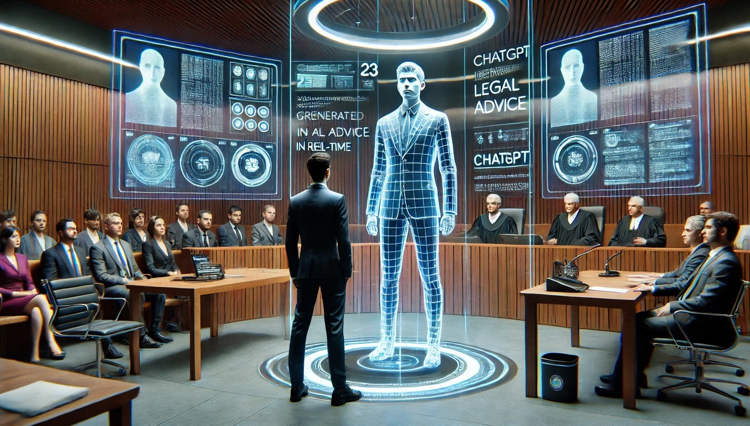

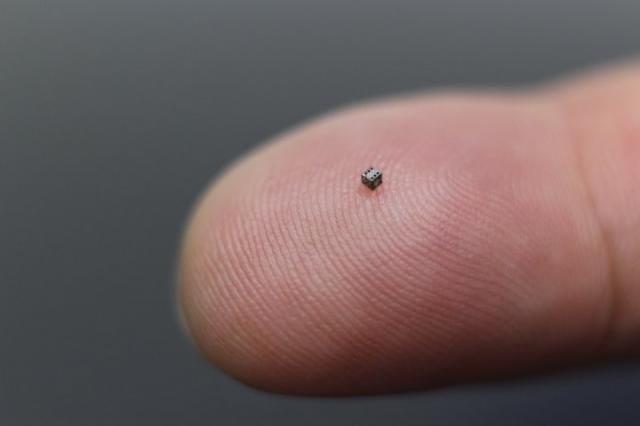

A team of welders from Mazda Motor Corporation in Japan recently showed off their skill by painstakingly welding the faces of a 1mm die.

Photos of a metallic die barely visible on a person’s fingertip and a magnified up-close photos showing the elegant welding keeping all six facets together recently went viral on Japanese social media, leaving a lot of people impressed. Although you’d be hard-pressed to use this type of die in a real-life situation, the fact that people are actually capable of this sort of impressive feat is incredible. It goes to show you that nothing is impossible, regardless of how hard it is.

The photos received a lot of attention on Japanese Twitter, with around 30,000 likes and thousands of comments. Most people couldn’t believe that welding the faces of a six-faced 1mm die was even possible, while some praised the artisans for their technique and their patience.

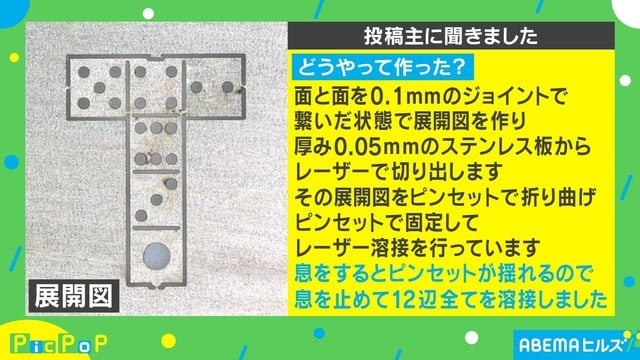

It was soon revealed that the minuscule die was the creation of a team at Mazda Motor Corporation who started out by creating all the facets in a T-shape, then bent them into a cube using fine tweezers. Finally, all the facets were finely welded together by a welder who had to hold their breath during the process.

Apparently, the team challenged itself to create ever-smaller dice ever since the ultra-fine division was inaugurated at Mazda. They started at 100 millimeters about four years ago, and have since been shrinking their creations down to 1 millimeter.

“Like surgery, we are welding by holding the die with tweezers while looking at a screen. Breathing causes the hand to move, so it is a work best down while holding your breath,” on of the welders involved in the project said.

The die is made from 0.05mm-thick stainless steel plates and may just be the smallest die ever made.