A team of six undergrads in the Netherlands have come up with a brilliant use for wasted fruit – they’re converting it into leather!

The eco-friendly project – titled ‘Fruitleather Rotterdam’ involves transforming rotten fruit into a durable, malleable, leather-like material. It started off as a school assignment at the Willem de Kooning Academy in Rotterdam, in which design students were supposed to set up a flash retail event. After brainstorming, this particular team decided to tackle the problem of food wastage as well.

“The academy gives us a perfect view over Binnenrotte Square in Rotterdam, where they have a market each Tuesday and Saturday,” said Hugo de Boon, one of the students involved. “We saw how the square would be completely littered with food waste (at the end of the day), so we realised this was a problem we would want to solve from a designer’s point of view.”

After some research, they figured out that over 7,000 pounds of food were being wasted each day at the market, and lots or stand owners were dumping the food illegally to avoid paying for proper disposal. So the kids started collecting leftover fruit directly from the vendors – mangoes, oranges, nectarines, apples, and more – and used it to manufacture a leather-like material.

They’ve refused to reveal the exact manufacturing details, calling it a “group secret”, but de Boon broadly explained the process: they start by deseeding the fruit and mashing it all up. Then they boil it to kill bacteria and prevent it from rotting. After cooling it, they spread the paste on a “specific surface” that is “crucial in the drying process”. Once dried, the Fruitleather is ready for use.

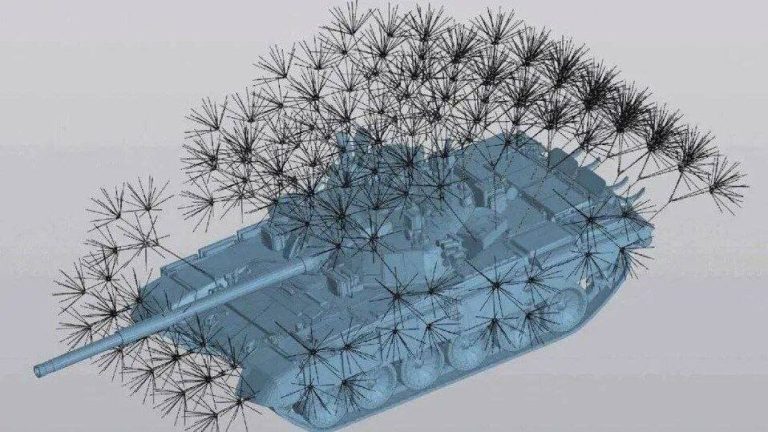

For starters, the team created a bag completely out of fruitleather, to showcase its various properties. But according to de Boon, the versatile material can be used to make furniture, accessories, and clothing as well. “Many people make the mistake that we are currently just making bags,” he said, speaking to Mashable. “We used the bag as a visual for the public to show that products can be made out of the material, but it is the material itself that we produce.”

Fruitleather has garnered lots of interest from various manufacturers. A car seat maker has already contacted the students about buying their product, but they’re now focused on improving their manufacturing process for more output and better quality. “The production process will need to increase for the demand as well, but before making that step, we first want to answer the questions that we as a team have about the material,” de Boon said.

Fruitleather has garnered lots of interest from various manufacturers. A car seat maker has already contacted the students about buying their product, but they’re now focused on improving their manufacturing process for more output and better quality. “The production process will need to increase for the demand as well, but before making that step, we first want to answer the questions that we as a team have about the material,” de Boon said.

“What we want to achieve with this project is to create awareness for the problem that is food waste, and show that there is a solution,’ the Fruitleather Rotterdam official website states. “Food isn’t trash, you just need to find a different purpose for the resisting material. We used our design background to come up with a solution.”

Photos: Fruitleather Rotterdam/Facebook