3D-printed homes aren’t exactly new, but the rapid progress made in this new industry never cease to amaze us here at Oddity Central. Earlier this year we wrote about a Chinese company that used a specially designed 3D printer to create large ec0-friendly housing in record time. Another construction company has now perfected the process, making it possible to assemble a fully functional home in just three hours!

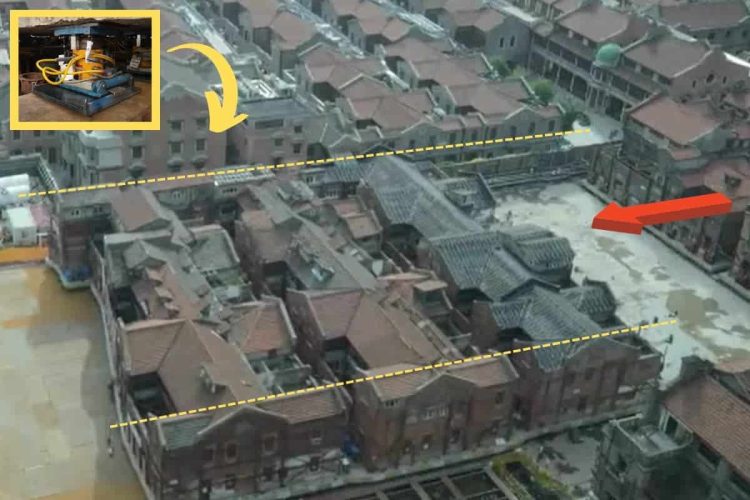

The revolutionary new technology was developed by Zhuoda Group, in Xi’an, central China. On July 17, they put up a two-storey sample villa built from pre-constructed components that were printed in a factory and later lifted into place using a crane. The instant villas cost only about 3,500 yuan ($564) per square meter, which is far lower than the current industry standard.

Zhuoda representatives have revealed that their own 3D homes use ink made of a different base, other than cement. They haven’t actually revealed the material, but they claim that it’s a lot cheaper and more durable. In fact, they insist that their villas will last at least 150 years, and can withstand high magnitude earthquakes. The material is fireproof and waterproof, and it contains no formaldehyde, ammonia, radon, or other harmful compounds.

The company revealed that 90 percent of the villa was fabricated in a factory, a lot like how other products like shoes and phones are made. Everything, including interior decoration, wiring, plumbing, kitchen fittings and other facilities are created through 3D printing technology.

The villa was assembled during a presentation that began at 9.30 am – the workers stacked each module of the house like building blocks, using a crane. The living room was assembled first, followed by the bedroom, kitchen, and bathroom on the first floor, and the terrace, bedroom, and utility rooms on the second floor – all in under three hours.

“Thanks to our special materials, our rate of assembling houses is really fast,” said Zhuoda group vice president Tan BuYong explained. “Since 90 percent of the houses we build are completed in a factory prior to the actual on-site construction, we only need to do on-site follow-up work to complete a build. This not only avoids the pollution caused by traditional construction sites, but also dramatically reduces construction costs by thinking about houses as a traditional manufactured product.”

The company is trying to patent the technology, and it will soon be made available to consumers on a mass scale. They’re planning to introduce customization as well – the material can be modified to resemble jade, marble, wood, granite, and other decorative textures. Customers will even have the option of embedding Chinese herbs within the walls for ‘built-in aromatherapy’.

via 3Ders.org